All of our technical installation to produce water and fish with a high and stable quality and as well as the implementation of experiments are continuously monitored for values such as temperature, salinity, pressure, pH and water supply.

Hatchery

The production of our experimental fish starts in the hatchery. Here fertilised eggs (spawn) from Atlantic salmon are delivered from Stofnfiskur on Iceland four times a year. In total we produce approx. 100,000 laboratory fish per year, of which most are used in vaccine trials where the purpose is to develop better and safer vaccines for the aquaculture industry. We usually use fresh water with a temperature of 6 degrees, and then it takes just less than 2 months before the eggs hatch and become alevins. From then it takes just over 2 months before the alevins are ready for start feeding in fish tanks in the fry hall.

Photo: The hatchery consists of 8 drawers and a total of 16 hatching slopes. The level tanks can supply the various drawers with 4 different temperatures at the same time, which means that we can supply fish at an earlier or later time if desirable.

Photo: The fry hall comprises 16 fish tanks with a capacity of 500 litres. These are configured such that we can have different temperatures. This is done to speed up or hold back the fish so that we can always provide the desired size to customers.

Fry hall

After almost 2 months as fry in the hatchery, the yolk sack is empty. The fish are then moved to larger fish tanks in the fry hall and are ready to start feeding. In order to stimulate the fish to feed, they are exposed to light 24 hours a day, and the temperature is gradually increased to 12°C. To begin with, there are approximately 5,000 fish per square metre fish tank. As they grow, they are sorted according to size in different tanks. When the fish are around 5 grams they are moved from the fry hall to the RAS system for further growth until they are ready for experiments.

RAS-systems

In the production of salmon, large volumes of fresh water is used before they are transferred to seawater. Although we in Norway have plenty of access to fresh water, this is a scarce resource in many parts of the world. In recent years the aquaculture industry has therefore invested heavily to develop systems that reuse fresh water, so-called recycling aquaculture systems, or RAS. Such systems enable the production of salmon in locations where access to fresh water is restricted, and leads to fewer interventions in our fresh water resources.

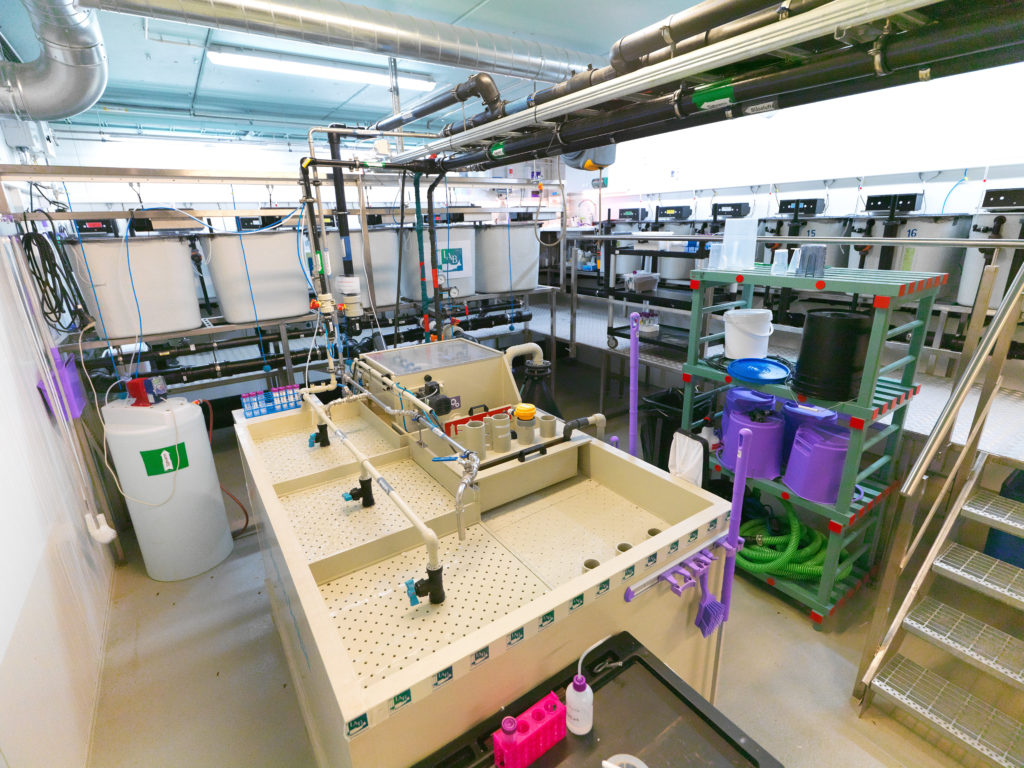

ILAB has adopted this technology, and has established two RAS systems that we use to produce fish that subsequently be used in experiments. When the fish are approximately 5 grams they are moved from the fry hall to the RAS system. Here the fish will grow to the right size, usually 20-30 grams, before being used in vaccine trials.

Fish that are not used in vaccine trials continue to grow in the RAS system. At around 50 grams they are returned to the flow-through systems where they can continue in fresh water or become smoltified and used in seawater experiments.

Photo: Our RAS system comprises two separate modules that both supply 8, 1,800 litre fish tanks with recycled fresh water.

Photo: The Post-smolt hall consists of 10 1,800 litre fish tanks where the fish can grow until they reach the right size for the various experiments carried out in the aqua halls or disease halls.

Post-smolt hall

When the salmon are adapted to seawater, they are called post-smolt. Large salmon in seawater are often used in experiments where the purpose is to improve fish health by combating sea lice and amoebic gill disease, or by optimising feed, reducing stress or by studying growth and development using biochemical and physiological methods.

To produce large salmon for use in seawater experiments, ILAB has its own hall with flow-through seawater dedicated for this.

Aqua facility

In the aqua hall, all experiments that don’t require disinfection of the water are carried out. This includes feed experiments, toxicity experiments and basic studies of the fishes’ physiology and behaviour.

ILAB has 10 aqua halls where some are leased to permanent customers with long-term contracts. The other halls are available for shorter assignments. All of the aqua halls are designed to provide great flexibility. Tanks are connected in twos, and have a common mixing tank where the salinity and temperature can be adjusted. This mixing tank also permits the addition of different gases and chemicals to alter the water’s composition. Here researchers can choose whether they want to conduct experiments with fresh water, brackish water or full seawater. They can also choose temperatures between 4 and 30 °C, different lighting conditions (natural light, 12:12 or 24 hour light) and feeding regimes.

Overall, the aqua halls contain 20 150 litre fish tanks, 102 500 litre fish tanks, 7 2,500 litre and 3 1,800 litre fish tanks. Some of the halls can be connected to chlorinated drains and be used as infection/quarantine halls for aquatic organisms.

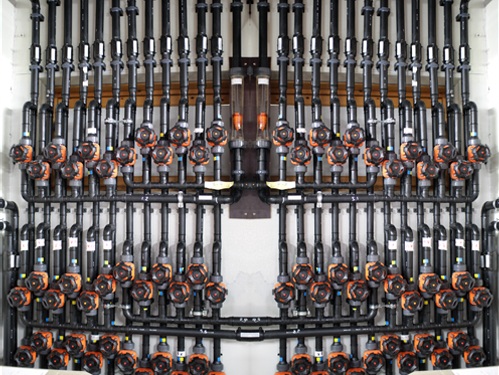

Bilde: Ventiler for å stille inn vannkvaliteter.

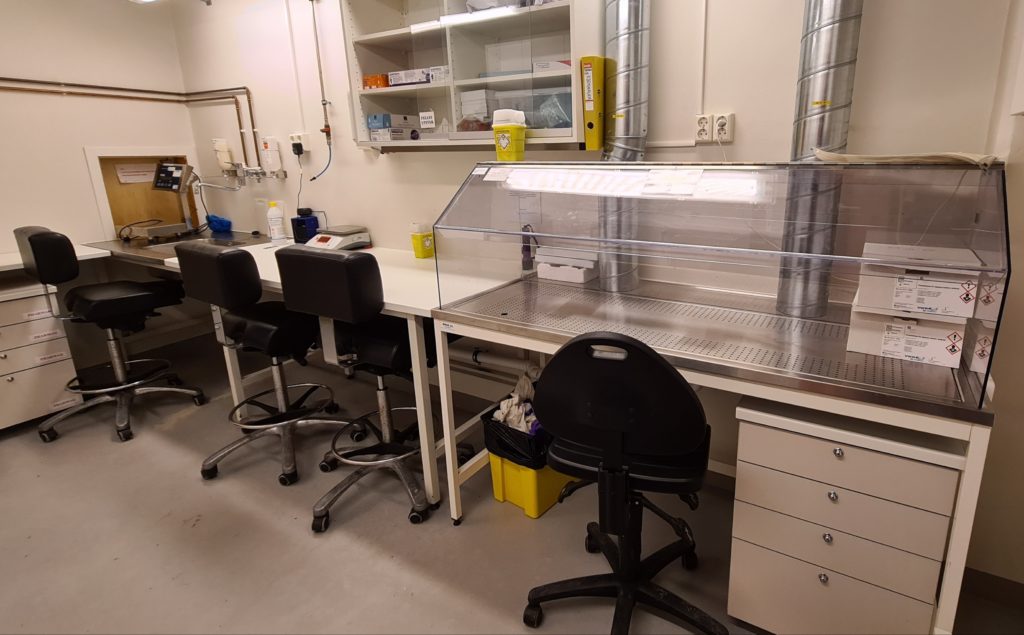

Photo: The pathology laboratory that is used to take samples from sick fish from disease halls.

Challenge facility

In the disease halls infection experiments and experiments with GMO/GMM that require disinfection are carried out.

The disease halls consist of 9 disease cells and a larger disease hall. The disease cells consist of 8 150 litre fish tanks with 4 mixing tanks where different temperatures and salinity can be applied. It is also possible to exchange the 150 litre tanks with larger 500 litre tanks if the experiment requires this. Overall, the disease halls contain 53 150 litre fish tanks, 29 500 litre fish tanks and 3 1,800 litre fish tanks.

For taking samples of fish, the disease halls have a dedicated lab connected to the disinfection system and approved for work with infectious agents and GMO/GMM.

Raw material test facility

ILAB has its own fish hall where one quickly can test how different ingredients in feed for salmon fry affect growth. The hall comprises 18 150 L fish tanks where it is possible to quickly test how different ingredients in feed for salmon fry impact their growth.

The fish hall can also be used to test and compare different commercial fish feed for salmon fry.

Photo: Raw material test hall with fish tanks and RAS module.

Technical facilities

ILAB has the operational responsibility for a number of large technical facilities that are necessary to provide stable and good experimental conditions for fish. Most of these facilities are built with med complete backups which means that there are two sets of facilities for:

-

Seawater supply

-

Fresh water supply

-

Disinfection of wastewater

-

Energy (heating and cooling)

-

Oxygen

-

Lighting